Bay Tek Entertainment develops and builds ticket-redemption games that provide entertainment at arcades across the country. In early 2017, the sales team at Bay Tek was seeing a lot of success closing sales on games. Two games in particular – Pop the Lock and Spin-N-Win – were significantly outpacing production forecasts. Trying to assemble all the games in-house would have increased Bay Tek’s lead time immensely, leading to unsatisfied customers. To avoid that, Bay Tek decided to outsource to MCL.

Pop the Lock

In late 2016, Bay Tek had designed a brand new game called Pop the Lock. By 2017, however, sales for the game had outpaced forecasting by nearly 90%. By February 2017, Bay Tek outsourced all production of Pop the Lock to MCL. The partner companies worked closely to successfully integrate the game into MCL’s high volume value stream, and they decided it would be best for Bay Tek to continue supplying the parts, from wires and connectors to the CNC-routed wood for the game cabinet; and MCL would provide the skilled workers, space to build the game and shipping logistics. Since Bay Tek had already assembled the game, it trained the MCL team that took on the task.

Over the course of six weeks, MCL went from assembling zero Pop the Lock games to 33 per week. From February through July 2017, MCL shipped nearly 500 of the games. Now, all Pop the Lock games are manufactured at MCL.

Spin-N-Win

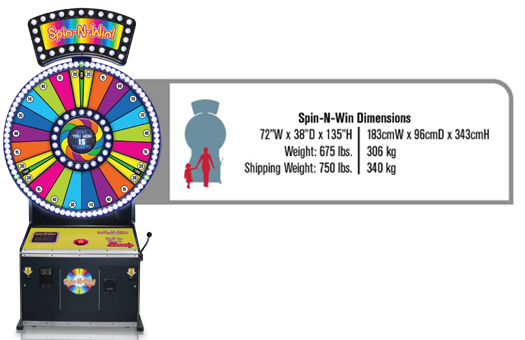

Spin-N-Win is a game that Bay Tek gained as part of its acquisition of Skee-Ball in February 2016. A staple piece in game rooms across the nation, Bay Tek redesigned Spin-N-Win in early 2017. The new redesign increased demand for the classic title, and orders for the game were soon outpacing forecast numbers by nearly 65%. The unexpected demand caused a backlog in Bay Tek’s low volume production cell, however, and lead times were growing.

Given MCL’s performance on Pop the Lock, the game maker turned to its contract manufacturing partner again in June 2017 to help with Spin-N-Win. This particular ticket-redemption game is much larger than most traditional games, however, and requires significantly more labor. Nevertheless, the two companies worked closely once again to integrate this second game into MCL’s high volume value stream.

This required MCL to expand the production cell and the team of skilled workers needed to do the job, while Bay Tek took care of the training and inventory. Within the first month of moving Spin-N-Win to MCL, nearly 20 games were manufactured and shipped. This brought Bay Tek’s lead time down by nearly two weeks. Now Bay Tek relies on MCL to manufacture all Spin-N-Win games as well.

Results

Bay Tek’s decision to outsource Pop the Lock and Spin-N-Win to MCL allowed the ticket-redemption game developer to significantly increase sales in 2017 and better satisfy customer demand on other ticket-redemption titles. The additional production capacity that MCL provided allowed Bay Tek to sell $8 million more in games than they could physically assemble in-house, while Bay Tek’s customer satisfaction remained intact. By taking on the extra volume for these titles and helping Bay Tek avoid potentially lost orders due to increasing lead times, the door has been opened for Bay Tek to outsource other games to MCL as needed.