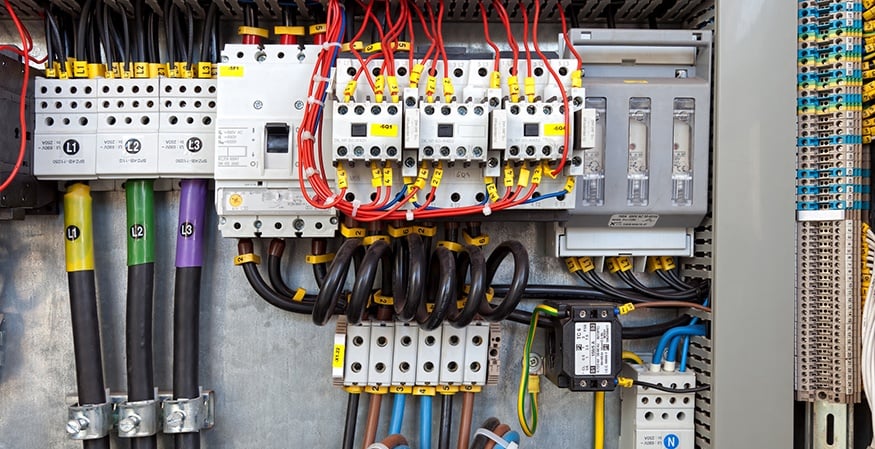

Whether an electrical control panel operates the dump box on a 360-ton mining truck or keeps a product flowing through an assembly line, it’s important to ensure that you’ve got the ideal design and manufacturing process for the job. After all, the control panel is essentially the brains of the whole operation, and offers no room for error with your design. For OEMs thinking about outsourcing control panel assembly, however, there’s a lot to consider before choosing a contract manufacturing partner. To help you make the best choice for your control panel assembly, here are 4 things to look for in a contract manufacturing partner:

1. Strong Design & Engineering Capabilities

No matter how flawless a design may seem on paper, it’s always possible that problems may occur during production. For this reason, joining forces with an assembly partner that has an experienced engineering department is extremely valuable. Your contract manufacturing partner’s engineers will thoroughly examine all designs for manufacturability and function, in an effort to find anything that could cause headaches down the road. If any problems happen to come up once the project is in production, those same engineers will be onsite to assess the situation quickly, communicating with you as needed.

2. Robust Supply Chain Management

Because there can be thousands of components that make up a control panel, it’s important that you choose an assembly partner with an extensive supply chain and the manpower to handle the purchasing logistics. It’s impossible to build something that you can’t procure parts for, and having the right partner means having someone that will work with you every step of the way to ensure your control panel is built with the right parts and at the most economical price.

3. ISO-Certified

A quick way to identify the best assembly partner is to look for suppliers who are ISO-certified. This means that the company has set processes in design, production, and quality; follows them faithfully; and conducts audits to ensure that the processes are performing at optimal levels. As a customer, it means you will always get a high-quality control panel, because the process is repeatable and scalable.

4. Dedication to Customer Partnerships

It’s one thing to be really great at building control panels. It’s a completely different story, however, when your assembly partner is also truly dedicated to your partnership. When you entrust your control panel designs to an outside team, you should know they have experienced, service-minded people who will do whatever it takes to get the job done right. And if you need to contact them after you’ve received the control panel, they will be there ready to answer any questions you have. Your control panel assembly partner should also be eager to learn about your industry, so they can understand you and your assembly needs better. This fosters an even stronger partnership and growth for both of you.

If you’ve never outsourced your control panel assembly before, the process can be tricky. However, we’ve put together A Beginner’s Guide to Contract Manufacturing to help you understand what it is and how it can solve 5 common production pain points. Click the button below to download your free copy now.