CASE STUDY

Console Design Modifications Result In Annual Six-Figure Cost Savings For construction Equipment Manufacturer

As part of MCL’s commitment to being a great partner to customers, our engineering team and production technicians are always looking for opportunities to improve efficiencies in the design, production and cost of assemblies. That commitment led MCL to suggest two operator console design modifications to a customer that manufactures construction equipment. Implementation of both modifications resulted in annual six-figure cost savings.

Cost-Saving Opportunity #1: Console Decal Material

The MCL purchasing team found it difficult to source a specific material for the console decals. The original design specified a very expensive, high-tech material that’s mainly used in the aerospace industry.

SOLUTION

In consult with the MCL engineering team, the purchasing team researched and identified several comparable materials that were more readily available and cost significantly less than what the customer’s engineers had been using. After the customer chose the best material for the application from the new options, MCL’s engineers made the proper adjustments.

RESULTS

The change in materials reduced the cost of each decal by about 80% and didn’t affect the way MCL manufactured them, allowing for uninterrupted production.

Cost-Saving Opportunity #2: Console Lighting

The construction equipment is used day and night, so the operator console lighting is critical. The original design called for an index card-sized circuit board containing two dozen LEDs and utilizing through-hole technology. Depending on the console size, the design required anywhere from six to ten light boards. There were also two versions of the light boards: a 12-volt and a 24-volt.

During installation, the light boards required spacing to prevent them from shorting out. Spacers were used to offset the boards from the enclosure, however this increased the amount of hardware necessary and installation time. The small bulbs on the LEDs were also somewhat fragile and could easily shatter during installation or regular use/service.

During installation, the light boards required spacing to prevent them from shorting out. Spacers were used to offset the boards from the enclosure, however this increased the amount of hardware necessary and installation time. The small bulbs on the LEDs were also somewhat fragile and could easily shatter during installation or regular use/service.

SOLUTION

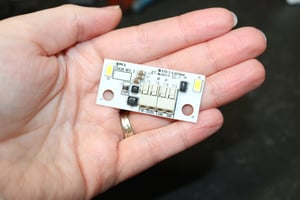

MCL designed a surface-mount LED light board about the size of a flash drive that can be used between 5 to 30 volts. The two LEDs on the new light board produce significantly more light than the original, reducing the number of light boards needed to properly backlight a console.

RESULTS

The new LED light board is 80% smaller than the previous design, a quarter of the cost and produces more light. Furthermore, since the new light board can be used on applications from 5 to 30 volts, there is only one part number to manage instead of two.

The more streamlined design of the LEDs minimizes breakage and allows for flush mounting that doesn’t need to be offset, reducing the amount of hardware needed and installation time. Additionally, the light boards can easily be daisy chained, making it simple to wire a full console with multiple light boards.

The reduced size and added strength of the console light boards ultimately made it possible for the customer to strategically place them out of sight to reduce clutter inside the enclosures and out of the way of service technicians.

The more streamlined design of the LEDs minimizes breakage and allows for flush mounting that doesn’t need to be offset, reducing the amount of hardware needed and installation time. Additionally, the light boards can easily be daisy chained, making it simple to wire a full console with multiple light boards.

The reduced size and added strength of the console light boards ultimately made it possible for the customer to strategically place them out of sight to reduce clutter inside the enclosures and out of the way of service technicians.

MCL’s partnership with this customer demonstrates our commitment to finding the best, most efficient way to manufacture effective assemblies. To learn how MCL can help your organization improve an assembly, request a design review through the MCL Sales and Engineering Team at 866-822-4100 or sales@mcl.bz.

Would you prefer to call us? Feel free to give us a ring at 866.822.4100