The term “outsourcing” used to carry a negative connotation. Today, however, more and more OEMs are seeing it as a helpful—and sometimes necessary—option. One instance where it can be especially helpful for OEMs is when they don’t have all the tools, space or people they need to mass produce electro-mechanical assemblies. Rather than trying to rally the team and strain resources, an OEM can avoid a lot of headaches by outsourcing to a domestic contract manufacturing partner.

For any OEM considering outsourcing, here are four assets a contract manufacturing partner can provide when building electro-mechanical assemblies:

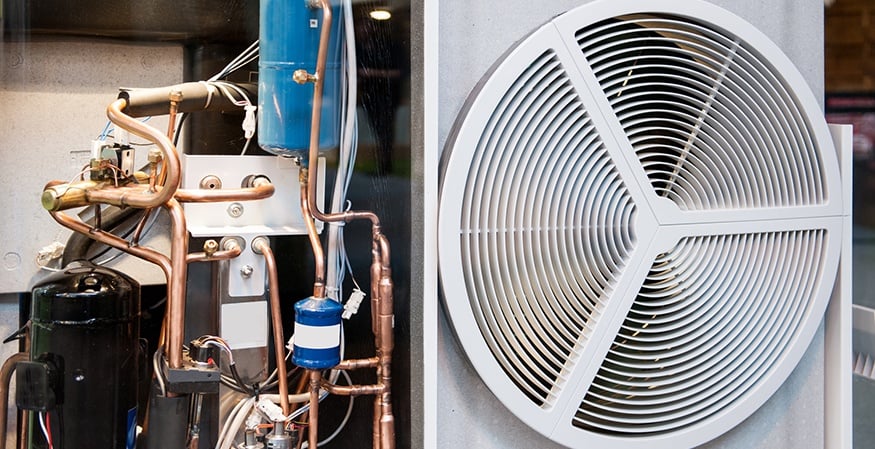

The Right Tools for the Job

Whether it’s a special hand tool, a CNC mill or a 2-ton, fully-automated wire cutting and crimping machine, contract manufacturers will have everything needed to efficiently process and build any electro-mechanical assembly. A contract manufacturing partner will research and invest in the latest technology to ensure it is doing the best job possible, in the most efficient way. Additionally, a contract manufacturing partner will provide the proper testing to ensure the electro-mechanical assembly will function as designed.

Manufacturing Space

Floor space can be difficult to find in a manufacturing facility, and overloading an area isn’t safe or efficient. A contract manufacturing partner will designate space on its production floor to build the assembly so an OEM doesn’t have to add space to an existing building. That way, OEMs can focus on core competencies and use existing floor space to increase output of the finished product, ultimately leading to an increase in profitability.

A Highly Trained Labor Force

In the midst of a skilled labor shortage, it can be difficult for OEMs to find workers who have electrical and mechanical skills. Whether in the engineering or production department, it’s crucial to have the right people in place. For example, a mechanical engineer shouldn’t be the only engineer working on an electro-mechanical design. And on the production floor, someone without mechanical assembly experience can be a safety concern. A contract manufacturing partner takes care of recruiting and training the skilled workers it will need to carry out the services the company offers.

Quality Processes

Building one electro-mechanical assembly can be simple. But replicating that process perfectly for hundreds – or even thousands – of assemblies is where it gets difficult. A contract manufacturing partner takes measures to perfect the production process and ensure the quality of each component it builds, creating detailed parts lists, work instructions, and even testing protocols. This guarantees OEMs will receive the highest quality outcome for each and every assembly, each and every time.

While each OEM may have its own reasons to outsource electro-mechanical assemblies, many of the benefits are recognized across all industries. If your organization is looking to outsource to a contract manufacturing partner, download our free Prospective Supplier Checklist to help objectively determine the best partner for your organization. Click the button below to access your copy.